Essential Tips for Choosing Disposable Microtome Blades?

Choosing the right disposable microtome blades is crucial for successful sectioning in laboratories. The quality of these blades can significantly affect your results. Understanding the various factors that impact blade performance is essential.

When selecting disposable microtome blades, consider the material and sharpness. Some blades are designed for specific tissues, while others are more versatile. Not all blades are created equal. Testing different brands might uncover better options for your needs.

Additionally, think about the ease of use. Some blades come with features that enhance handling and precision. However, this might add to your costs. It’s not uncommon to find that the cheapest options don’t always provide the best performance. Reflect on your lab's requirements and budget before making a decision.

Understanding Disposable Microtome Blades and Their Uses

Disposable microtome blades are essential tools in histology.

They are designed for cutting thin sections of tissue. Their main advantage is convenience.

You can use them without the need for sharpening. This saves time and effort in the lab.

When selecting disposable microtome blades, consider the type of tissue you will cut.

Different blades work better with specific materials. For instance, harder tissues may require blades with a different angle.

Always check the specifications before making a purchase.

It’s important to match the blade to your needs.

Tip: Keep an eye on blade sharpness. Dull blades can lead to uneven cuts.

This affects the quality of your samples.

Be prepared to replace blades frequently, especially when working with tough tissues.

Another tip is to handle blades with care. Improper handling can lead to accidents.

Always prioritize safety in the lab.

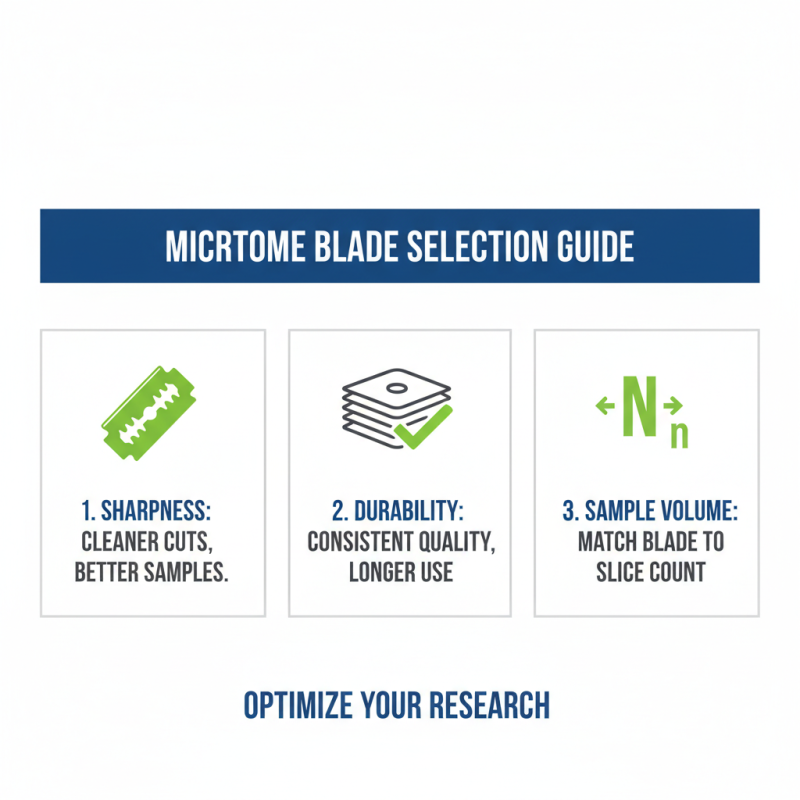

Key Factors to Consider When Choosing Microtome Blades

When choosing disposable microtome blades, several key aspects come into play. The blade's sharpness is crucial. Sharp blades provide cleaner cuts. This enhances your sample quality. Blades that dull quickly lead to rough sections. This might compromise your research findings. Consider how many slices you need. Some blades perform better with fewer samples.

Material is another important factor. Different materials yield various results. Some blades are made from high-quality stainless steel. Others may use different alloys. The thickness of the blade also matters. Thicker blades can be more durable but may limit the finesse of the cut. Conversely, thinner blades yield finer slices but may break more easily.

Weight and ease of handling are worth considering too. A lighter blade may feel more comfortable to use over time. However, balance is key. A well-balanced blade helps maintain control. Finally, look into user feedback. Sometimes, reviews highlight issues not visible in specifications. Finding a blade that feels right is essential to your workflow.

Material Types and Their Impact on Blade Performance

When selecting disposable microtome blades, understanding the material types is crucial. Each material significantly influences blade performance. Most commonly, blades are made from stainless steel, ceramic, or carbon steel. Stainless steel blades are popular due to their durability. They provide sharpness and resistance to rust. However, they may dull faster with extensive use.

Ceramic blades, on the other hand, offer a distinct advantage in terms of sharpness retention. Their hardness allows for smoother cuts, ideal for delicate samples. One study indicates that ceramic blades can maintain sharpness up to 50% longer than stainless steel. This is essential when working with sensitive materials, such as biological samples. However, they are more fragile and can chip easily.

Carbon steel blades are less common but can provide excellent cuts when sharpened properly. They require more care to prevent rust. Users often report that these blades do not last as long as stainless steel or ceramic. Balanced decisions must weigh durability against the quality of cuts. Be prepared to adjust your choice based on specific project needs. The right blade material can make a significant difference in overall workflow efficiency.

Essential Tips for Choosing Disposable Microtome Blades

| Material Type | Blade Thickness (µm) | Cutting Performance | Typical Use Cases | Shelf Life |

|---|---|---|---|---|

| Stainless Steel | 30 | High | General histology | 2 years |

| Carbon Steel | 20 | Moderate | Routine trimming | 1 year |

| Ceramic | 25 | Excellent | Ultra-thin sections | Indefinite if stored correctly |

| Plastic Coated | 15 | Good | Educational use | 6 months |

Evaluating Blade Size and Compatibility with Microtomes

When choosing disposable microtome blades, size and compatibility play crucial roles. The standard blade sizes typically range from 20 mm to 30 mm in width. A microtome that is not compatible with the chosen blade can lead to poor slicing, impacting overall specimen integrity. Reports indicate that improper blade size can result in a 25% increase in slicing errors. Accuracy is vital for histopathology, where precise sections are mandatory for diagnosis.

Compatibility also extends to the microtome type. For instance, rotary and sliding microtomes can have different requirements. A blade designed for a rotary microtome may not perform properly in a sliding microtome, potentially compromising results. Studies show that selecting the wrong blade type increases the likelihood of a poor cut by 30%. It’s important to verify the specifications of both the microtome and the blades.

Even seasoned technicians can encounter challenges. A common oversight is assuming all blades fit universally. Additionally, blades that are too new may pose risks of chipping or snapping if applied incorrectly. Contrast these details with user experiences, where many professionals find themselves needing a reliable setup that avoids such pitfalls. Regular review of blade compatibility can aid in improving workflow and reducing waste in lab settings.

Maintenance Tips for Maximizing Blade Longevity and Performance

Maintaining disposable microtome blades is crucial for efficient specimen preparation. Research indicates that improper handling can lead to reduced blade lifespan by up to 30%. Regular maintenance practices can significantly enhance performance and longevity, making blade selection more efficient.

Tips for extending blade life include ensuring that blades are stored in a clean, dry environment. Humidity can negatively affect blade sharpness. Regularly inspect blades for any signs of corrosion or damage. Dispose of damaged blades immediately. Remember, a dull blade can cause tissue distortion, which can affect research outcomes.

Another key aspect is proper cutting technique. Use a consistent speed during sectioning. A gentle touch can help maintain blade sharpness longer. Conversely, using excessive force might lead to premature blade failure. According to industry studies, cutting at the wrong angle can also lead to less optimal results, compounding the issues faced when using dull blades. A mindful approach in both maintenance and operation can yield superior results in histological applications.

Essential Tips for Choosing Disposable Microtome Blades

This chart displays the cutting quality and durability scores of various disposable microtome blades. Selecting the right blade involves considering both cutting performance and durability for optimal results in slicing samples.